Why do high-frequency transformers have to be led out with leads?

31/01/2019

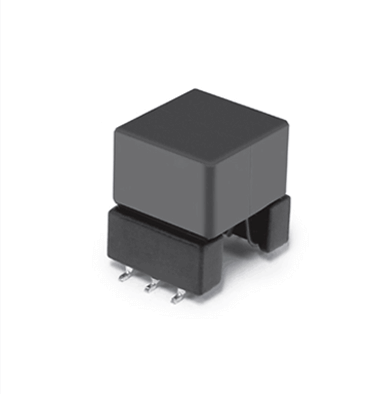

31/01/2019The high-frequency transformer is a power transformer with a working frequency exceeding the intermediate frequency (10 kHz). It is mainly used for high-frequency switching power supply transformers in high-frequency switching power supplies, and also for high-frequency inverters in high-frequency inverter power supplies and high-frequency inverter welding machines. Variable power transformer. Why do high-frequency transformers have to be led out with leads?

It is convenient to use the plug-in power supply plug-in itself, but there are three disadvantages: one, the output current is large, the secondary wire diameter is thick, if it is easy to PIN 缠 with its own wire, the solder is easy to short-circuit, solder After the rise, the skeleton fulcrum is higher; second, the difficulty of the column plate is increased; third, the creepage distance between the secondary and the magnetic core is not enough, and additional insulation measures need to be added;

The lead-out is generally secondary. In order to increase the safety distance between the primary, if the foot is directly hung, the primary and secondary are difficult to meet the high-pressure requirements! From the operational point of view, it is convenient to do flying lines!

In the development of products, in order to achieve small size or low height, in order to save space, the transformer can not use products with larger volume or skeleton to meet the requirements of safety regulations. Due to the limitation of space and skeleton itself, safety is allowed. Make the flying line longer distance to meet the safety distance requirements.

The above is the analysis about why the high-frequency transformer should be led out with lead wires. I hope I can help you.

For some high-frequency transformers, because the skeleton is small, the transformer manufacturer's technicians recommend replacing one of the three-layer insulated wires with a casing. Is the volume after casing addition smaller than that of the three-layer insulated wire?

One: First of all, we must understand the development of three-layer insulated wire. When there is no three-layer insulated wire, the primary and secondary are all used for enameled wire, but to meet the 6.4mm safety distance, we must add a retaining wall, and then we will have three layers of insulated wire. The layer insulation wire has a withstand voltage of 4000V, so the removed retaining wall is insulated with three layers, and the casing is only responsible for isolation. Of course, if he puts the entire winding wire on the casing, the above is not true.

Second: The transformer manufacturer's suggestion should be only the casing for the inlet and outlet. If the enameled wire is used, the thickness will be much smaller throughout the day. In fact, the main thing is to see how your safety requirements are. It can be replaced by enameled wire. If the incoming and outgoing lines and edges are isolated. it is also fine.

Three: After adding the casing, the volume is of course much larger. The ideal solution: after you have wrapped a group, use insulated yellow wax thick (or electrical insulation tape wrapped around a circle) in the other group, it is better than You save a lot of volume with a sleeve. I personally think: it is best to use yellow wax thick, because it is resistant to high temperature, high pressure, insulation performance is very good, the temperature is within 80 ° for 24 hours, no problem, and with electrical insulation tape, high temperature is not good, it is easy to be bad Drop it.

133-9291-8466

133-9291-8466

133-9291-8466

133-9291-8466 semcms

semcms

13392918466

13392918466